Quality Control (QC) Measures Explained

Redemption centres (RCs) are paid a service fee to accurately sort and count deposit-bearing beverage containers. Inaccurate container counts can pose a financial burden on the New Brunswick Beverage Containers Program.

QC is thus a high priority for Encorp, and it should also be a priority for your RC.

We use a systematic sampling method to monitor the level of compliance and report on a regular basis to individual RCs with the necessary adjustments.

We have provisions in place to ensure that our QC measures remain accurate:

- leading inspections at the QC facilities a minimum of four times per year (blind recounts of bags/tubs and verification of procedures);

- reviewing the QC measures periodically by an independent statistician to ensure validity;

- randomly selecting one RC per year for the Accelerated Mode. The randomly selected RC does not suffer any consequences from being placed in Accelerated Mode.

More information on our current QC program can be found in the documents below.

Questions or Concerns on your RC’s Performance?

Angela Dow – Assistant Controller & Quality Control Officer

506.389.7328

Mélissa MacMullin – Director of Operations

506.800.1424

[email protected]

Note that RC operators who wish to better understand the process can also visit (by appointment) Encorp’s third-party service providers’ facilities (Hebert’s Recycling and Rayan Investments) where bulk bags/tubs are QC’d.

Accuracy Trend Report

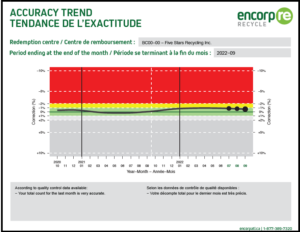

Encorp sends each RC a confidential Accuracy Trend Report, showing the RC’s accuracy trend line as it evolves. The goal of this monthly reporting tool is to help RC operators stay on top of their QC results and take action earlier if they are under-reporting or over-reporting their container counts. RC operators receive these reports from Encorp via email.

The Accuracy Trend Report takes into account the average QC data for the RC from several months, which provides a reliable estimate of the accuracy over time, and is not affected by one-off mistakes. Encorp considers RCs whose average container count errors on their bulk bags/tubs are between +2% and -2% to have a good accuracy trend – and no corrective actions are needed.

An example of such a report – featuring two fictitious RCs – one with a good accuracy trend followed by one with a more worrisome accuracy trend – is available below. The FAQs provided on pages 3 and 4 provide insights on interpreting the graphs shown in the report.

Note that at any time, if an RC is worried about its accuracy trend and how its RC is performing, it can request a detailed monthly report from our Director of Operations, Gilles Doucette. We are happy to chat with RC operators about their centre’s performance to help identify areas of improvement.

Accuracy Awards

Twice per year (December and June), Encorp gives out Accuracy Awards to RCs that have shown excellent accuracy trends over the past 12 months (their estimated average error is between +1% and -1%, and their estimated relative standard deviation of the errors is less than 5%). Each RC that receives an Accuracy Award is sent a prize to share with members of its staff and management team so that all employees can be rewarded for their work. Encorp hopes this recognition among peers will foster the sharing of best business practices among RC operators, and will be looking at ways to facilitate this knowledge exchange.

Award Winners!

- Cole’s Redemption Center (Harvey York)

- Valley Redemption Centre Inc. (Moncton)

- Cocagne Variety Ltd. (Cocagne)

- Southside Redemption Centre (Fredericton)

- K & R Bottle Exchange Ltd. (Rexton)

- Porter’s Bottle Exchange (Doaktown)

- Sully’s Bottle Depot (Chipman)

- Recyclage Caraquet (Caraquet)

- Centre de recyclage COOP (Rogersville)

- P & S Redemption Center (Perth-Andover)

- Brooks Redemption Centre (Hartfield)

- Acadia Bottle Exchange LTD (Cap-Pelé)

- Brooks Redemption Centre (Hartfield)

- Denton’s Bottle Exchange (Minto)

- Acadia Bottle Exchange LTD (Cap-Pelé)

- Brooks Redemption Centre (Hartfield)